Our Neopentyl Glycol (NPG) is a high-purity, synthetic organic compound classified as a diol or glycol. It appears as white, crystalline flakes or powder with a mild, characteristic odor. Its unique molecular structure—featuring two primary hydroxyl groups attached to a central carbon atom that is also bonded to two methyl groups—confers exceptional stability, resistance, and performance benefits that make it a crucial intermediate in high-performance polymer synthesis.

Neopentanediol, NPG

C5H12O2

126-30-7

25kg/bag, 500kg/bag

Reach, ISO9001

Global Reach: Our Neopentyl Glycol has been successfully exported and applied in key markets across the globe, including but not limited to Brazil, UAE, Saudi Arabia, Egypt, Indonesia. Our product has consistent quality and ability to meet diverse international standards.

Equivalent Alternatives: Our product has served as a reliable alternative to Dow chemical, BASF, Eastman Chemical, Mitsubishi Gas Chemical, Perstorp for several local manufacturers, helping them reduce costs with comparable (or even superior) results in performance.

The primary application. NPG is a key monomer for resins used in: Powder Coatings:For appliances, automotive parts, and architectural applications requiring durability and weatherability. High-Solid Industrial Coatings:For machinery, and coil coatings. Polyester Polyols: For producing polyurethane resins, coatings, and elastomers.

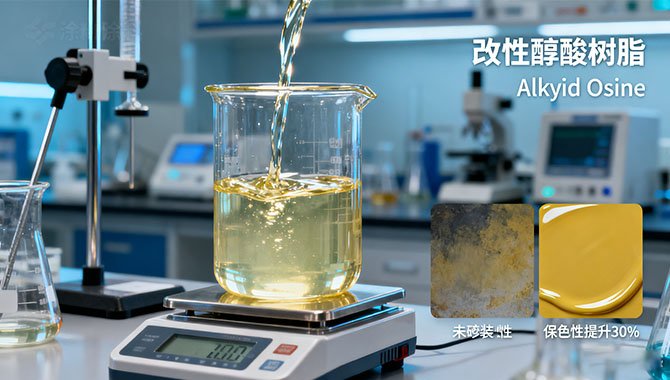

Modifies alkyd resins to improve color retention, hydrolytic stability, and durability in decorative and industrial paints.

Used to synthesize complex esters that serve as high-performance base stocks for jet engine oils and compressor lubricants, offering excellent thermal stability.

Production of adipate and other ester plasticizers for PVC and other polymers, providing low volatility and good low-temperature flexibility.

Exceptional Hydrolysis Resistance: The neopentyl structure sterically hinders attack on the ester linkage, dramatically improving the longevity of polyesters in humid or wet environments.

Outstanding Thermal & UV Stability: Imparts superior resistance to yellowing, degradation, and loss of gloss in polymers exposed to heat and sunlight.

Excellent Chemical Resistance: Enhances resistance to acids, alkalis, and solvents in coating resins.

High Purity: Typically 99.5% minimum purity, ensuring consistent performance in sensitive polymerization reactions.

Low Volatility & High Melting Point: Suitable for powder coating applications.

We are committed to providing high-quality Ethyl Acrylate that meets stringent international standards. Our focus on innovation and sustainability ensures that our products not only enhance your applications but also align with evolving environmental regulations and industry trends.