Methyl Ethyl Ketone Peroxide is a peroxide solution acting as initiator for curing unsaturated polyester resins in fiberglass reinforced plastics at room temperature.

MEKP, 2-Butanone peroxide

C8H16O4

1338-23-4

20KG DRUM, 200KG DRUM, 1000KG IBC

ISO9001

Global Reach: Our Methyl Ethyl Ketone Peroxide has been successfully exported and applied in key markets across the globe, including but not limited to: [Russia, Brazil, Vietnam, UAE]. Our product has consistent quality and ability to meet diverse international standards.

Equivalent Alternatives: In Europe market, our product has served as a reliable alternative to United Initiators, AkzoNobel, Arkema for several local manufacturers, helping them reduce costs with comparable (or even superior) results in performance.

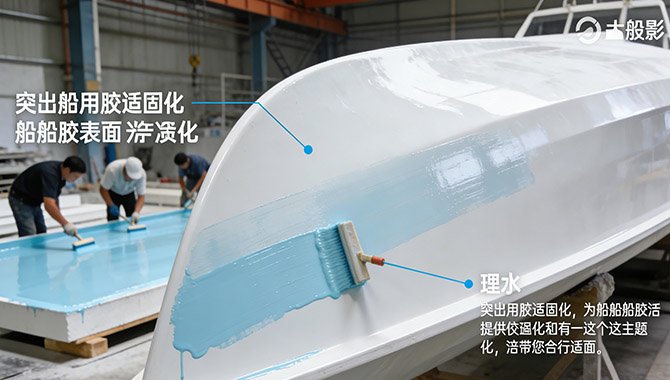

Serves as the primary catalyst for room-temperature curing of fiberglass reinforced plastics (FRP) used in marine, automotive and construction industries.

Used as initiator for acrylic sheet production and surface coatings requiring controlled polymerization.

Ensures complete cross-linking of corrosion-resistant vinyl ester resins used in chemical tanks and pipes.

Provides reliable curing initiation for boat hull gelcoats, ensuring superior surface finish and water resistance.

Initiates curing of resin-based flooring compounds in factories and warehouses.

Catalyzes the polymerization process in synthetic marble manufacturing.

Controlled Reactivity: Optimized for composite manufacturing and resin curing.

Stable Formulations: Ensures consistent curing performance and shelf life.

Safety Focus: Detailed handling and storage guidelines provided.

We are committed to providing high-quality Methyl Ethyl Ketone Peroxide that meets stringent international standards. Our focus on innovation and sustainability ensures that our products not only enhance your applications but also align with evolving environmental regulations and industry trends.