Methyltetrahydrophthalic Anhydride (MTHPA) is a low-melting, saturated cyclic anhydride. It typically appears as a light yellow to white solid or liquid (depending on isomer ratio). It is a key curing agent for epoxy resins, offering a favorable combination of low viscosity, long pot life, and excellent electrical and thermal properties in the cured product. Its low volatility reduces exposure risks compared to some other anhydrides.

MTHPA, 4-Methyl-1,2,3,6-tetrahydrophthalic anhydride

C9H10O3

19438-64-3

25KG Bag, 200KG Drum

ISO9001

Global Reach: Our Methyltetrahydrophthalic Anhydride (MTHPA) has been successfully exported and applied in key markets across the globe, including but not limited to the United States, Germany, Japan, South Korea, and India. Our product has consistent quality and ability to meet diverse international standards.

Equivalent Alternatives: Our product has served as a reliable alternative to Huntsman, Polynt, Dixie Chemical, Milliken Chemical, Shangdong Helishi Chemical for several local manufacturers, helping them reduce costs with comparable (or even superior) results in performance

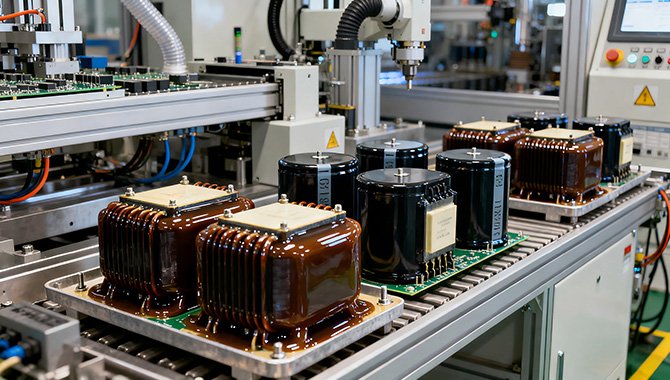

Extensively used as a high-performance curing agent for encapsulating and potting transformers, capacitors, and semiconductor devices. It provides excellent electrical insulation, thermal stability, and resistance to thermal cycling.

Serves as a primary hardener in the epoxy resin systems for printed circuit board (PCB) substrates (FR-4). It imparts high glass transition temperature (Tg), good mechanical strength, and flame retardancy.

Employed in the vacuum infusion molding process for manufacturing large composite structures like wind turbine blades. Its low viscosity and long pot life facilitate thorough wet-out of glass/carbon fibers.

Used in high-performance powder coatings and solvent-based coatings for appliances and machinery. It offers good color stability, chemical resistance, and mechanical properties to the cured film.

Balanced Processing and Performance: Our MTHPA offers an optimal balance of low initial viscosity, extended pot life, and high heat resistance in the cured epoxy, enabling easier processing and superior final product performance.

Excellent Electrical and Thermal Properties: The cured epoxy systems exhibit outstanding dielectric strength, high glass transition temperature (Tg), and good thermal stability, making them ideal for demanding electrical and electronic applications.

Consistent Quality for Reliable Curing: We guarantee strict control over isomer content and acid value, ensuring predictable and consistent curing characteristics, which is critical for automated production and product reliability.

Technical Expertise in Thermoset Systems: Leverage our formulation knowledge to optimize your epoxy/anhydride ratios, curing cycles, and final properties for composites, encapsulants, and coatings.

We are committed to providing high-quality Methyltetrahydrophthalic Anhydride (MTHPA) that meets stringent international standards. Our focus on innovation and sustainability ensures that our products not only enhance your applications but also align with evolving environmental regulations and industry trends.